Blog

Why Use Cordierite for Pizza Stones?

Posted by Tom Evans on 03-08-2022

Our range of refractory ceramics, such as cordierite and silicon carbide, are traditionally used as ‘kiln furniture’ for tableware, sanitaryware and other similar industries. They also turn up in more unexpected places though – from silicon carbide’s use in the electric vehicle battery industry to cordierite’s use for pizza stones. What is a pizza stone? A pizza stone is a square, rectangular, or circular plate used to hold a pizza during cooking, essentially acting as a baking tray that’s more…

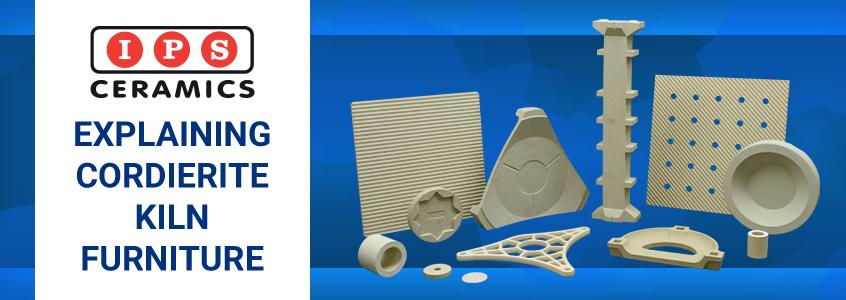

Explaining Cordierite Kiln Furniture

Posted by Callum on 28-08-2021

The term “kiln furniture” describes a range of products used by many industries to support items during heat treatment processes. If you have a ceramic item that needs firing in a kiln or furnace, you will probably need kiln furniture to ensure it keeps its shape, doesn’t break during firing, and don’t stick to/damage your kiln. IPS offers an immensely popular range of kiln furniture products made from cordierite. What types of products are in the range, what do they…

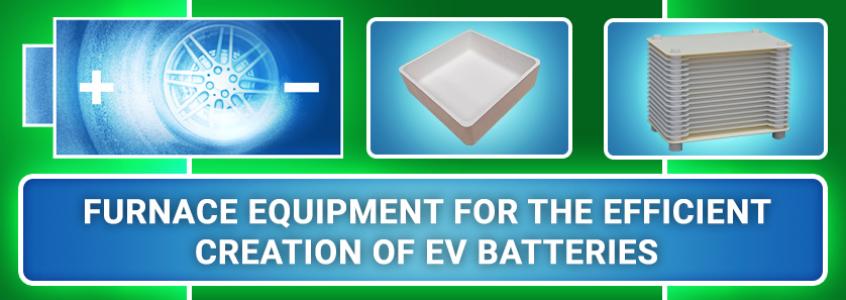

Furnace Equipment for the Efficient Creation of EV Batteries

Posted by Callum on 07-04-2021

The race is on to reduce the price of electric vehicles (EVs). In November 2020, the UK Government announced its plans to accelerate a greener transport future through a two-step phase-out of petrol and diesel cars to be enacted by 2035. Joe Biden’s presidency – still only a few months old – has also announced a range of green policies including the replacement of the 645K federal vehicle fleet with electric cars and an increased level of funding for green…

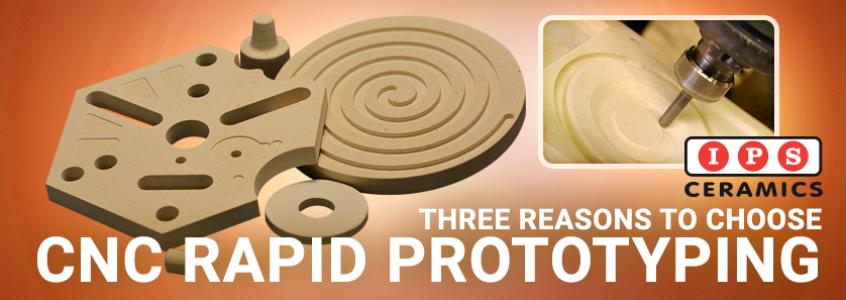

3 Reasons to Choose CNC Rapid Prototyping for Ceramic Components

Posted by Callum on 04-03-2021

At IPS Ceramics, we offer a rapid prototyping service for clients looking to develop new shaped supports (setters) for their firing or heat treatment processes. Using our CNC routers, we can either machine your own designs or create a bespoke design using our experienced in-house design team. But why should you choose CNC rapid prototyping for your product development project? In this article, we’ll look at three reasons whilst exploring the rapid prototyping process. What is CNC Rapid Prototyping? CNC…

Cleaning Guide for Kiln Shelves

Posted by Callum on 18-02-2021

IPS Ceramics understands that maintaining your kiln shelves is an extremely important part of glost firing. Neglected shelves (also known as batts and tiles) can result in flakes of wash getting onto your beautifully glazed surfaces or can cause kiln ware to stick to shelves where the glaze has previously dripped. To get the best life from your shelves, it is crucial to stay on top of cleaning tasks and to know how to apply a wash coating to your…

The Best Kiln Furniture Products for Sanitaryware

Posted by Tom Evans on 01-12-2020

Firing sanitaryware offers a series of unique challenges – sanitaryware products tend to be bulky and heavy items which place significant structural demands on kiln furniture; they can have complicated designs which aren’t easily supported by singular flat surfaces; and they are fired at relatively high temperatures (up to 1280 °C / 2340 °F). It’s a demanding industry which requires dependable solutions. IPS Ceramics have designed many specialist products for the sanitaryware industry. What are the most commonly used items…

Experts in Technical Ceramics

Established in its present form in 2009, IPS Ceramics evolved from the merger of several leading manufacturers of high-temperature ceramics, all bringing a bank of expertise. Today’s IPS team collectively boasts 250+ years of experience in ceramic technology, including design, material selection/specification and manufacturing. We can rapidly and expertly evaluate possible technical ceramic solutions for your specific application or a whole host of manufacturing, engineering and laboratory demands.

For more information on our services, please feel free to contact us today.