Blog

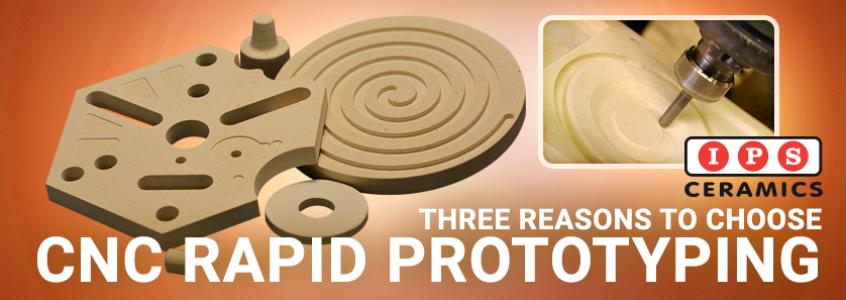

3 Reasons to Choose CNC Rapid Prototyping for Ceramic Components

Posted by Callum on March 4, 2021

At IPS Ceramics, we offer a rapid prototyping service for clients looking to develop new shaped supports (setters) for their firing or heat treatment processes. Using our CNC routers, we can either machine your own designs or create a bespoke design using our experienced in-house design team.

But why should you choose CNC rapid prototyping for your product development project? In this article, we’ll look at three reasons whilst exploring the rapid prototyping process.

What is CNC Rapid Prototyping?

CNC (Computer Numerical Control) machining is a manufacturing technique in which computer inputs control machining tools to create prototypes and end-use parts.

The first stage of the CNC process is to create the design for your prototype using SolidWorks software. When this design is finalised, the SolidWorks file will be uploaded to our CNC routers for them to machine into a machinable ceramic block. The end product will be your ceramic prototype.

For these prototypes, we usually use our unique machinable cordierite blanks, a specially formulated version of cordierite which can be fired repeatedly at temperatures up to 1300°C (2350°F).

Why Choose CNC Rapid Prototyping?

CNC rapid prototyping is ideal for product developers that need high-quality ceramics prototypes and testing samples. Here are 3 reasons why:

It’s Quick

For applications that require short lead times, CNC machining offers a quick solution. Following a finished 3D design, the tools used in this process work quickly, taking just a matter of hours to create a fully finished and ready-to-test ceramic prototype.

At IPS Ceramics, we maintain a stock of machinable cordierite blanks, meaning that your prototypes will be put into production as soon as the designs are ready. To reduce turnaround times, we are also constantly adding to our CNC machinery, having recently installed a second new CNC router to expand our production capacity.

It’s Accurate

As CNC machining is a computer-controlled process carried out using modern tools, it is a great way of producing accurate ceramic prototypes when exact dimensions are crucial. Our CNC machines can be relied upon to make parts to tolerances of +/- .05mm or better, ideal for manufacturing ceramic prototypes for our customers.

It’s Easy to Make Changes

Our prototypes work the first time but can occasionally need some fine-tuning for you to get your perfect product. Thanks to the digital nature of our process, altering designs can take mere minutes. The cost-effectiveness and ready availability of our machinable cordierite blanks means that producing updated prototypes is a quick and easy process too. This all greatly speeds up the process of perfecting your final design.

Rapid Prototyping from IPS Ceramics

We also offer machinable cordierite blanks which you can machine yourself. These blanks are available in sizes up to 500mm x 500mm x 70mm, allowing you to machine large prototypes with ease.

To find out more about custom cordierite components and rapid prototyping from IPS Ceramics, please feel free to contact us.