Rapid Prototyping

IPS Ceramics Rapid Prototyping

About IPS Ceramics Rapid Prototyping

The IPS Ceramics rapid prototyping service is unique in offering a CNC machined ceramic product that can be fired repeatedly to temperatures up to 1300°C (2350°F). This allows you to try out new designs through your firing or heat treatment process to assess suitability before committing to expensive new tooling. This is a chargeable service (however the cost will be discounted from your first production order).

Custom Cordierite Components

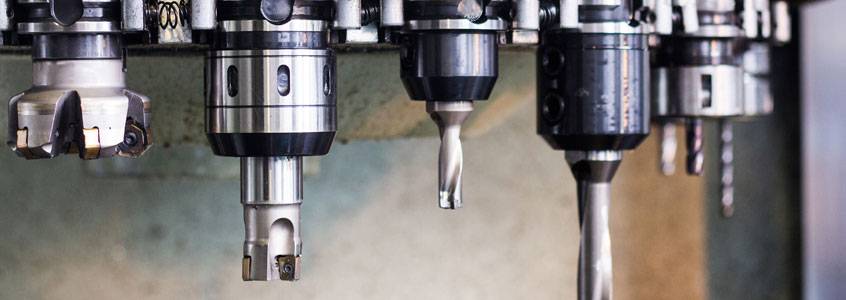

We can start with either your own CAD or SolidWorks design files, or with a bespoke design by our in-house team. We process the design to allow our precision CNC machining centre to cut your custom components from a blank made from our specially developed machinable cordierite material.

Our machinable cordierite has been pre-fired to ensure your finished custom components are dimensionally stable, and it exhibits a low coefficient of thermal expansion to minimise size changes in use. Blanks are usually available from stock so that items can be produced quickly; this also allows a fast turn-around of design changes where product optimisation is carried out.

Blanks are available up to 500mm x 500mm x 70mm (20in x 20in x 2.8in) allowing quite large prototypes to be machined. For more information about our custom components, please get in touch with our team.