Setters, Supports and Cranks

IPS Ceramics offers an extensive range of setters, supports, and cranks. Their main roles are to hold and support the ware in kilns / furnaces during firing. They are also often stackable, allowing you to maximise your kiln fill and reduce energy consumption.

IPS’ setters, supports and cranks are typically used by tableware and dinnerware manufacturers for biscuit, glost and decorating firings. The type of setter, support or crank that you require will depend on the precise level of support that your ware requires. You can find more about our different types of supports below.

THE BENEFITS OF IPS CERAMICS’ SETTERS / CRANKS

- Our Setters / Cranks are typically stacked several high to maximise kiln fill.

- Our Setters / Cranks can have integral legs for ease of use and reduced labour costs, or cemented legs for maximum flexibility and lower cost.

- Our Setters / Cranks produced by slip-casting have a smoother, more consolidated surface that minimises kiln dirt.

IPS CERAMICS’ SETTERS, SUPPORTS AND CRANKS RANGE

.

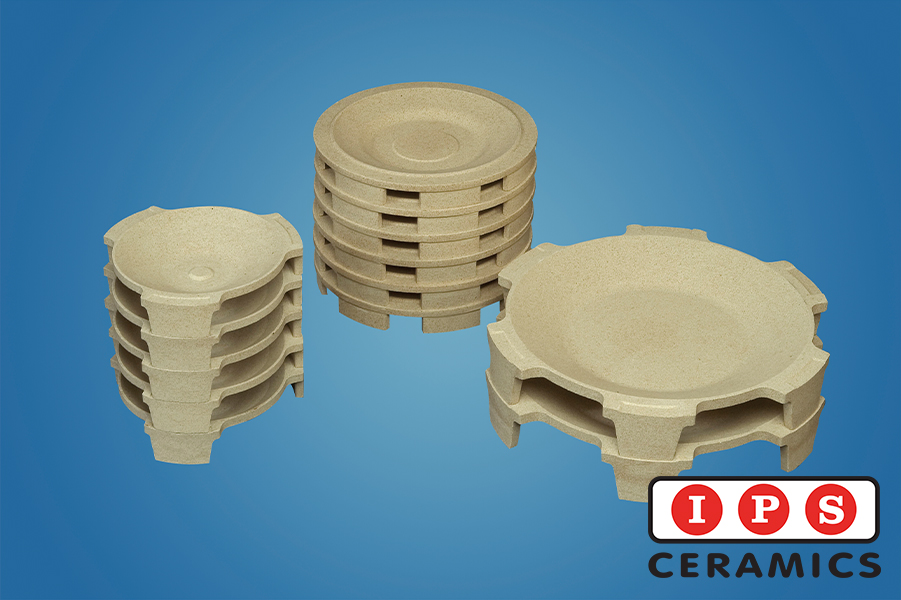

Profile Setters

Bone china, fine china and other vitreous ware require extra support during biscuit firing. Profile setters are designed to fully support the shape of the ware throughout the firing cycle, minimising distortion and maximising yields. Our profile setters are custom designed based on your exact requirements.

A rapid prototype service is available, allowing you to confirm your design produces the correct shape before committing to tooling. Our extensive range also includes bedding setters and more.

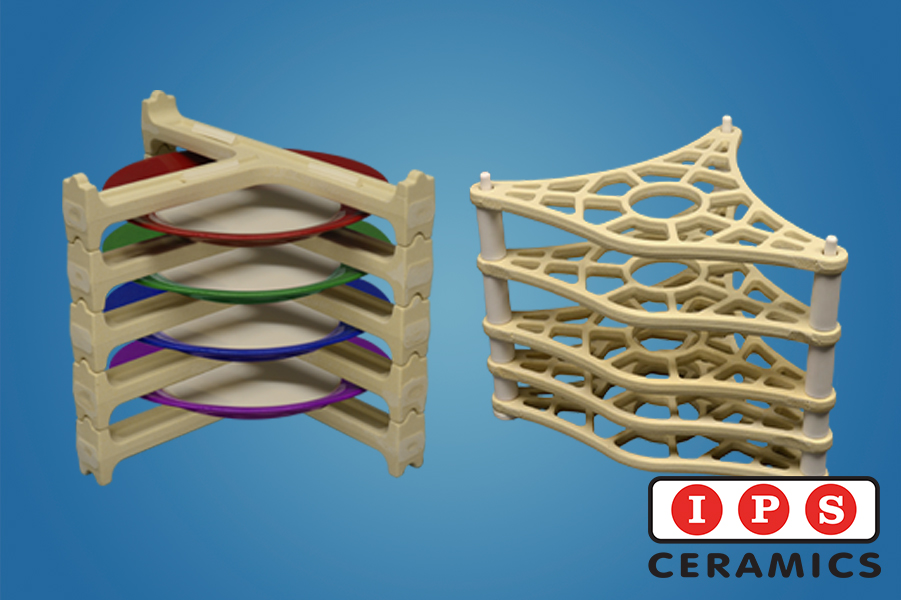

T-Cranks, Y-Cranks and Web Cranks

IPS Ceramics’ T-Cranks, Y-Cranks and Web Cranks are used to support plates, flatware and holloware during decoration and glost firing.

Easily stacked to maximise kiln-fill, the cranks support the ware at just 3 points on the foot, minimising the risk of plucking or sticking. The cranks can be loaded and unloaded without separating the stack and the light-weight design can help to minimise energy consumption.

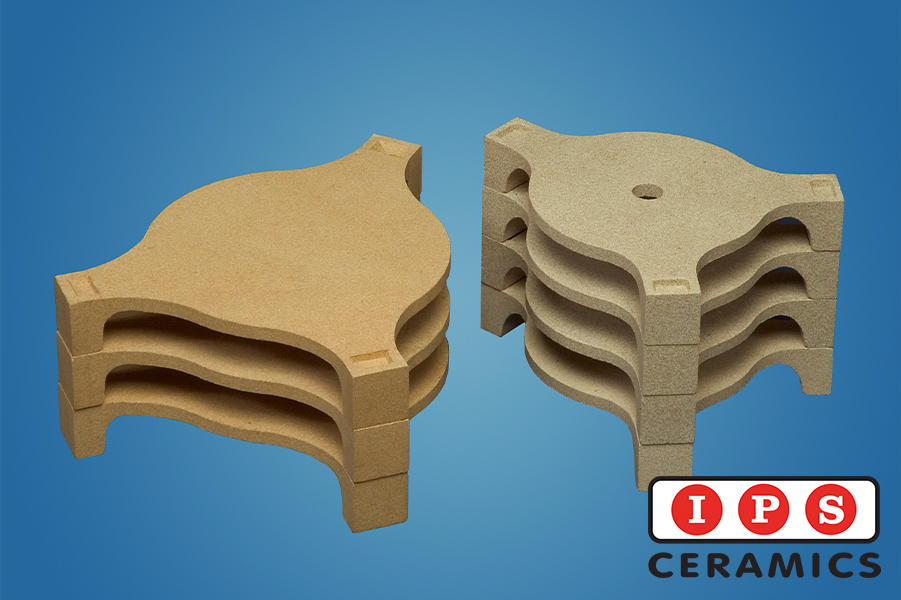

TFS Setters

Total Foot Support (TFS) setters are used where higher glost temperatures mean that the full foot of the plate needs to be supported. These setters are often used for once fired plates.

The legs can be spaced so that they can be loaded and unloaded without separating the stack.

Silicon Carbide Setters

Silicon Carbide Setters are generally used for customer firings above 1250°C (2280°F) where an improved resistance to bending is needed. They can also be used at lower temperatures to reduce weight and energy consumption.

They are made from either Nitride Bonded Silicon Carbide (NSiC) or Recystalised Silicon Carbide (ReSiC), allowing the setters to be made thinner/lighter and reducing the weight of refractory in the kiln/furnace.

Pin Cranks

IPS Ceramics’ Pin Crank Systems are typically used with porous ware that needs foot glazing. During glost firing, the ware rests on small ceramic ‘pins’ with the pins leaving only a small mark in the glaze that is easily polished. The system allows very high packing densities to be achieved to maximise kiln usage, whilst the ultra-low weight design gives outstanding energy efficiency.

The low-cost pins are used only once, but the crank frames are reusable.