Zirconia

Page Navigation

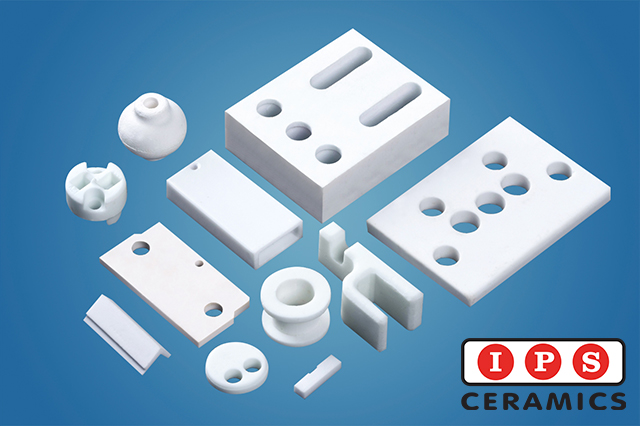

GENERAL OVERVIEW

Zirconia is a material with two distinct sub-types. Refractory type zirconia (also known as ‘fully stabilised’ zirconia) is used for extreme high temperature applications up to 2200oC (such as furnace linings). Engineering type zirconia (also known as ‘toughened’ zirconia or TZP) is used for mechanical components in high performance industrial equipment.

IPS Ceramics’ engineering zirconia is a very fine-grained, fully dense ceramic that is tough enough to survive engineering applications that would shatter other ceramics. Sintered to full density for maximum strength, it is tough enough to replace metals in a wide variety of applications. It exhibits exceptional abrasion resistance, ideal for use as ceramic bearings. It is also often used for industrial cutting blades and scrapers – the material can be ground to a sharp edge, and due to its toughness, it retains that edge for a long time.

We also supply Zirconia-Toughened Alumina for engineering applications where a more economical solution to full zirconia would be preferable. This is a version of alumina which is toughened by adding a small amount of zirconia during manufacture. It is typically used for industrial cutting blades for yarns and textiles, bearings and seals, pump and valve components, wire-drawing cones, rollers, and guides.

We also offer porous zirconia tiles that are used as sintering supports for firing ferrites and piezoelectric materials.

TECHNICAL INFORMATION

| Zirconia | |||

| Typical Information | Engineering Zirconia (ZTP) | Zirconia Toughened Alumina (ZTA) | Porous Zirconia (Fully Stablised) |

| Max. Usage Temperature | 100 °C / 200 °F | 100 °C / 200 °F | 1400 °C / 2550 °F |

| Bulk Density | 6.0 g/cm³ | 4.2 g/cm³ | 4.2 g/cm³ |

| Open Porosity | < 0.5 % | < 0.5 % | 30 % |

| Modulus of Rupture @ Room Temp. | 900 MPa | 350 MPa | 50 MPa |

| Modulus of Elasticity | 200 GPa | 300 GPa | — |

| Thermal Conductivity | 3 W/mK | 25 W/mK | — |

| Thermal Expansion at 20 – 1000 °C | 10 x10-6/K | 8 x10-6/K | — |

| KIC Fracture Toughness | 9 MPam1/2 | 6 MPam1/2 | — |

| Volume Resistance | 5 x 108Ωcm | > 1014Ωcm | — |

| Dielectric Constant | 29 | 10 | — |

| Dielectric Strength | — | 12 kV/mm | — |

| Typical Composition | |||

| ZrO₂ | 95 % | 80 % | 93 % |

| Y₂O₃ | 5 % | 20 % | — |

All figures are typical figures determined using laboratory test pieces and might not always be an accurate representation of production item.

PHOTO GALLERY

DOWNLOADS

RELATED PRODUCTS

|

|

|

| Alumina | Silicon Nitride | Steatite |