Kiln Batts, Plates, Tiles and Shelves

Batts are used as the basic kiln shelf support element in most kiln and furnace structures, forming a flat, rigid surface which carries the ware during firing, sintering or heat treatment. They are also known as “refractory tiles”, “plates” or “kiln shelves” depending on the industry.

They are typically made using large, high-capacity hydraulic presses with hardened steel moulds to give a product that is flat and uniform to tight tolerances. We also manufacture extruded batts (for heavy loads, helping to reduce refractory mass and energy consumption) and cast batts (for use in roller kilns, providing a clean and dust-free surface).

Kiln shelves have many variations in either size, shape, material or all these combining factors. They can be made from cordierite, high alumina, silicon carbide, or nitride bonded silicon carbide.

Types of Kiln Shelves, Batts, Plates and Tiles from IPS Ceramics

Selecting the right type of batts and kiln shelves will depend upon factors surrounding your production processes. These include the type of kiln, the temperature profile during firing, the size of your kiln shelves, the weight of the ware they must support, how the ware is supported, whether your kiln atmosphere involves oxidation or reduction, and the rate of firing and cooling.

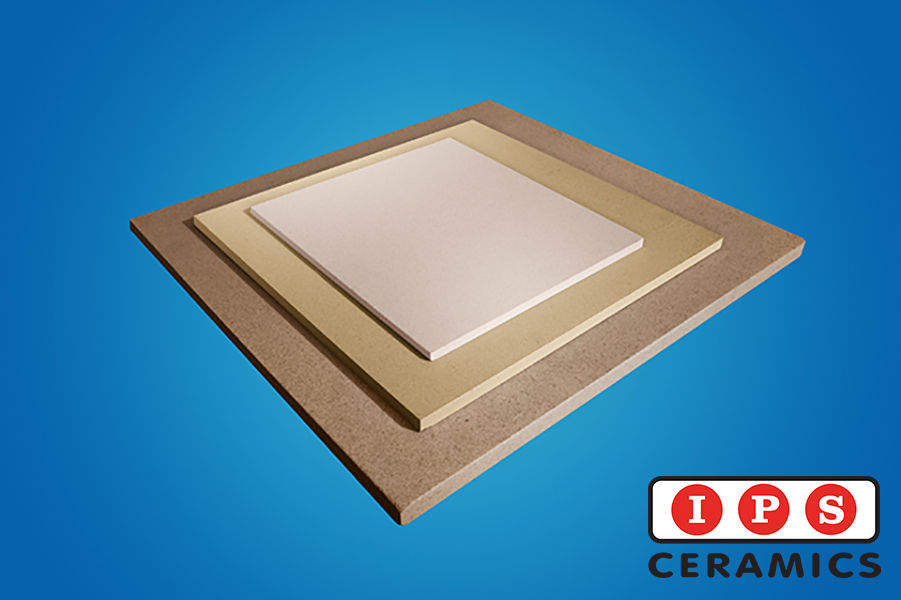

Plain Batts, Plates, Tiles and Shelves

Cordierite Batts, Plates, Tiles and Shelves are a core component of most kiln systems – flat, strong, and dependable. They are used throughout the ceramic industry, including biscuit, decoration and glost firings for tableware.

Silicon Carbide Batts, Plates, Tiles and Shelves

IPS Ceramics’ Silicon Carbide Batts, Plates, Tiles and Shelves are used in applications involving higher temperatures or heavier loads than would be suitable for cordierite products, or applications where weight/energy saving is required.

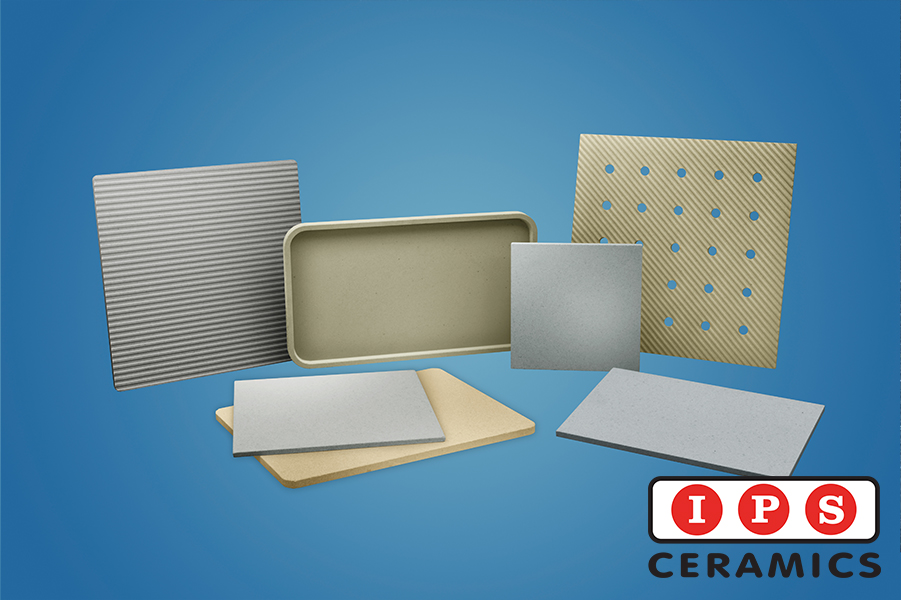

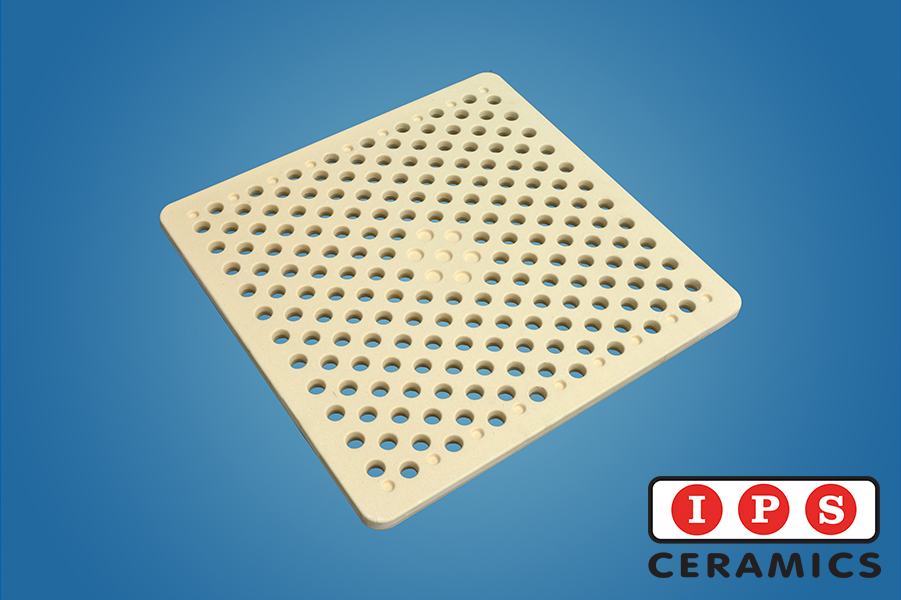

Feature Batts, Plates, Tiles and Shelves

Our Batts, Plates, Tiles and Shelves can be manufactured with additional features such as holes, grooves, slots, and recesses. These features typically provide extra functionality such as location-points, thermal breaks, or weight reduction.

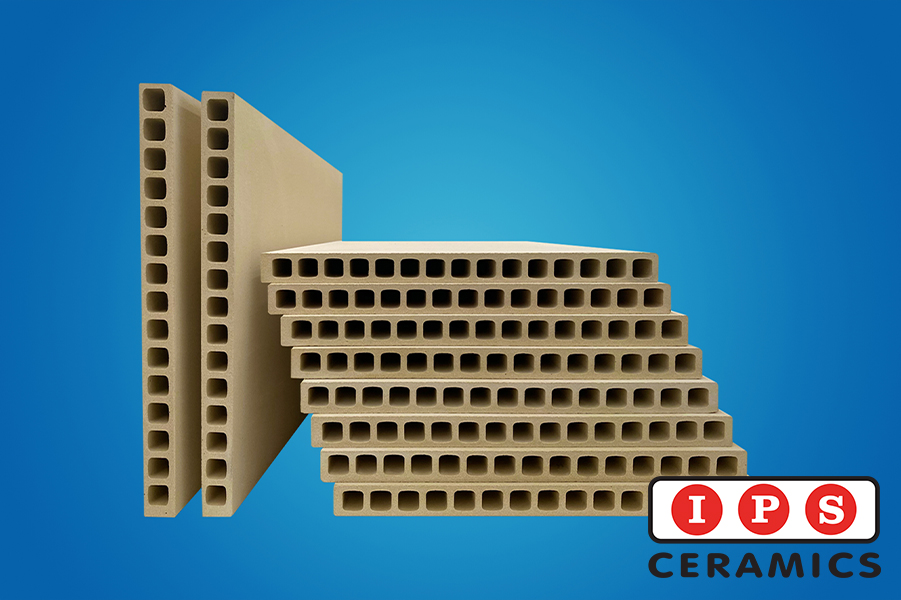

Extruded Batts, Plates, Tiles and Shelves

Extruded Batts, Plates, Tiles and Shelves are strong batts with channels running through the centre to reduce weight and energy consumption. They range from 16 mm to 48mm and have traditionally been used for applications involving extremely heavy loads (such as sanitaryware manufacture). They can be manufactured in larger sizes than pressed batts; these are usually used by industries such as the glass industry. Versions with thinner walls are also available.

Cast Batts, Plates, Tiles and Shelves

Cast Cordierite Batts, Plates, Tiles and Shelves are smoother and harder skinned than traditional batts made by hydraulic pressing. They are often used in roller kilns where the harder surface resists abrasion from kiln rollers, reducing kiln dirt and roller build-up. You can read more about them on our Feature Batt page.

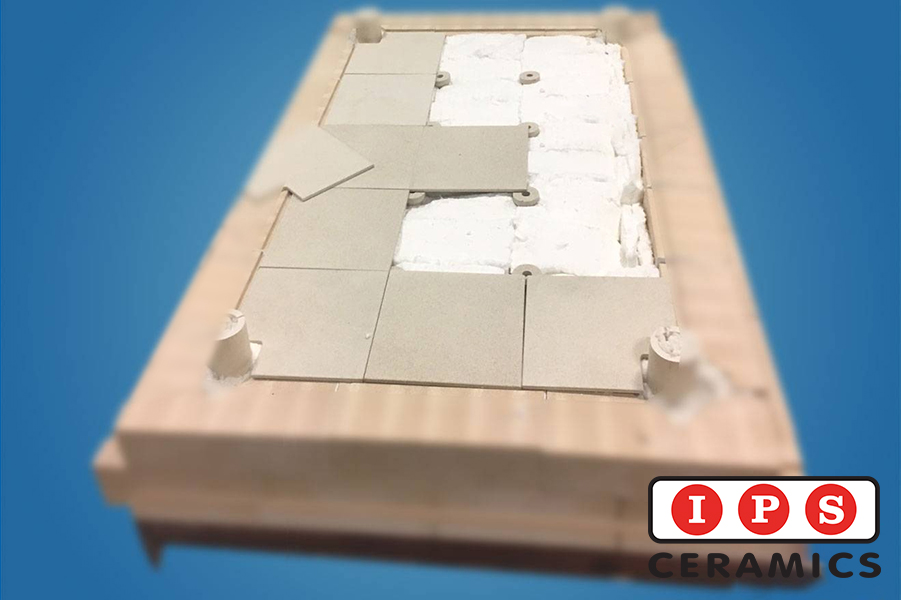

Cover Batts, Plates, Tiles and Shelves

Cover Batts, Plates, Tiles and Shelves are thin batts that are used to retain ceramic fibre used in kiln car bases or kiln walls. These batts provide a rigid surface that protects the soft fibre from the high velocity gas flows found in industrial gas kilns, significantly reducing kiln dirt and improving yields. They are also available in a lightweight, energy saving material. You can read more about IPS Ceramics’ Kiln Car Structures and their components on our Kiln Car page.

Alumina Discs, Plates and Tiles

Alumina discs, plates and tiles are used to support products during heat treatment processes. They are shaped to match the product.