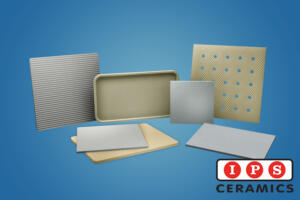

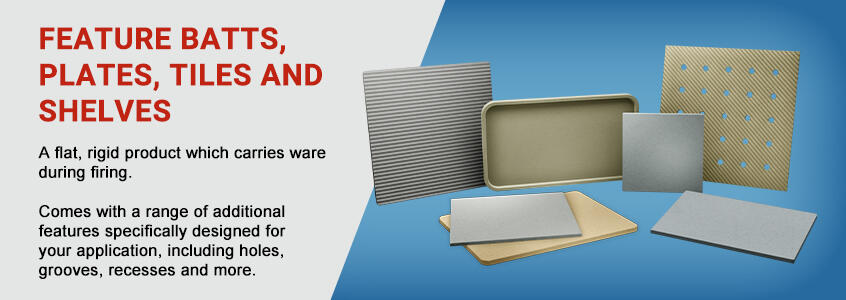

Feature Batts, Plates, Tiles and Shelves

Page Navigation

GENERAL OVERVIEW

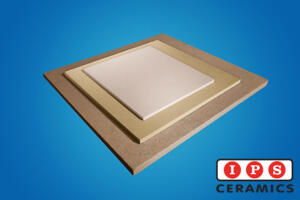

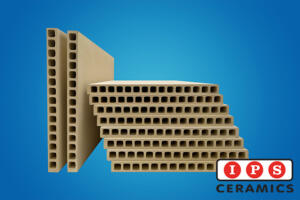

Feature batts, plates, tiles and shelves are used to support ware in the kilns and furnaces during firing and heat treatment. They can come with a range of features which cut into the batt (such as holes, slots, or recesses) or which slightly protrude out of the batt surface (such as grooves or pads). They can also be manufacturers to specific shapes, allowing them to support specific products during the firing process. They are useful in a range of industries, such as powder metallurgy.

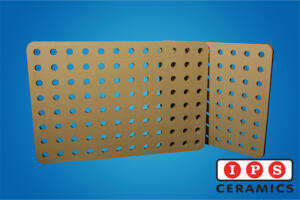

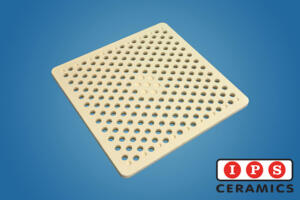

Perforated batts (batts with many holes through them) are often used to reduce weight or improve heat transfer during firing. Recessed batts (batts with recesses carved into them) can locate product on the batt, standardising product placement and preventing movement. Cast batts are smoother and harder than traditional batts, resisting abrasion from kiln rollers and reducing the production of kiln dirt. These features are often bespoke and built around the customer’s specific requirements.

TECHNICAL INFORMATION

| Feature Batts, Plates, Tiles and Shelves | |||

| General Information | |||

| Material Grade | Standard | Improved Surface | Fast Firing |

| Max Usage Temp. | 1300 °C / 2372 °F | 1300 °C / 2372 °F | 1300 °C / 2372 °F |

| Typical Physical Properties | |||

| Bulk Density | 1.85 g/cm³ | 2.00 g/cm³ | 2.00 g/cm³ |

| Apparent Porosity | 28 % | 26 % | 23 % |

| MoR @ 20°C | 15 MPa | 15 MPa | 13 MPa |

| MoR @ 1250°C | 13 MPa | 16 MPa | 15 MPa |

| CTE 20 – 1000 °C | 2.4 x10-6/K | 2.8 x10-6/K | 2.2 x10-6/K |

| Specific Heat @ 20°C | 1.0 kJ/kg.K | 1.0 kJ/kg.K | 1.0 kJ/kg.K |

| Typical Chemical Analysis | |||

| Al2O3 | 37 | 45 | 41 |

| SiO2 | 50 | 45 | 48 |

| MgO | 8 | 6.5 | 7 |

| Cast Batts, Plates, Tiles and Shelves | ||||

| General Information | ||||

| Material Grade | Cast (Saggar Material) | Cast (Standard Quality) | Cast (Enhanced Quality) | Cast (Thermal Shock Resistant) |

| Max Usage Temp. | 1200 °C / 2192 °F | 1250 °C / 2282 °F | 1250 °C / 2282 °F | 1250 °C / 2282 °F |

| Typical Physical Properties | ||||

| Bulk Density | 2.0 g/cm³ | 1.9 g/cm³ | 1.9 g/cm³ | 1.8 g/cm³ |

| Apparent Porosity | 24 % | 27 % | 29 % | 32 % |

| MoR @ 20°C | 12 MPa | 15 MPa | 30 MPa | 16 MPa |

| MoR @ 1250°C | 13 MPa | 15 MPa | 25 MPa | 15 MPa |

| CTE 20 – 1000 °C | 2.4 x10-6/K | 2.5 x10-6/K | 2.8 x10-6/K | 1.8 x10-6/K |

| Specific Heat @ 20°C | 1.0 kJ/kg.K | 1.0 kJ/kg.K | 1.0 kJ/kg.K | 1.0 kJ/kg.K |

| Typical Chemical Analysis | ||||

| Al2O3 | 43 | 42 | 38 | 44 |

| SiO2 | 47 | 47 | 51 | 44 |

| MgO | 7 | 7.5 | 8 | 10 |

All figures are typical figures determined using laboratory test pieces and might not always be an accurate representation of production item.

PHOTO GALLERY

DOWNLOADS

- IPS Ceramics Cordierite Datasheet (PDF)

- IPS Ceramics Catalogue (PDF)

- IPS Ceramics User Guide to Cordierite and Mullite Kiln Furniture (PDF)

RELATED PRODUCTS

|

|

|

| Plain Batts, Plates, Tiles and Shelves | Extruded Batts, Plates, Tiles and Shelves | Silicon Carbide Batts, Plates, Tiles and Shelves |