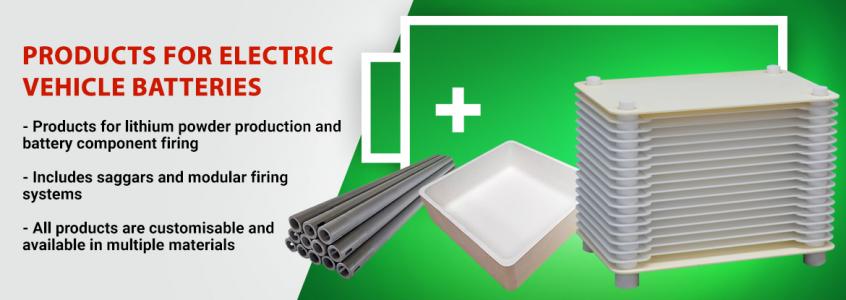

Electric Vehicle (EV) Battery Industry

Ceramic Products for the EV Battery Industry

With green movements on the rise and many countries looking to reduce their carbon footprint, the world has seen massive growth in electric vehicle battery production. The race is on to develop an industry standard battery which costs less, recharges quicker, holds more charge and lasts longer.

IPS Ceramics work closely with EV battery manufacturers to facilitate the development of these batteries. We have developed a range of ceramic products for use in the production of cathode materials and the firing of battery components, and are always looking for new projects to help the industry develop faster and further.

Our Most Popular EV Battery Products

Saggars Holds materials for lithium powder production during the calcination process |

Alumina Module Modular system used to hold battery components during firing |

Alumina Tiles Non-reactive, strong tiles used to support components |

Alumina Bubble Bricks Insulating bricks which are resistant to chemical attack by kiln atmospheres |

Silicon Carbide Heating Elements Used to fire furnaces using electric radiant heat. Rated up to 1650 °C. |

Silicon Carbide Radiant Tubes Used for indirect heating using gas burners |

Silicon Carbide Burner Nozzles Silicon Carbide Burner NozzlesHave less contaminates and a longer life than metal alternatives. |

Rollers Supports products and transports them through the kiln/furnace during firing |

Common Materials

Mullite / Cordierite Stable and resistant to thermal cracking, making it suitable to fast firings. Used as supports during firing/sintering. |

Alumina |

Silicon Carbide Higher strength material often used at higher temperatures. |

Links

- “IPS Ceramics – Furnace Equipment for the EV Battery Industry” Booklet [PDF]

- “Powering the Future: How Ceramics are Used to Make EV Batteries” [Online Article]