Blog

Explaining Cordierite Kiln Furniture

Posted by Callum on August 28, 2021

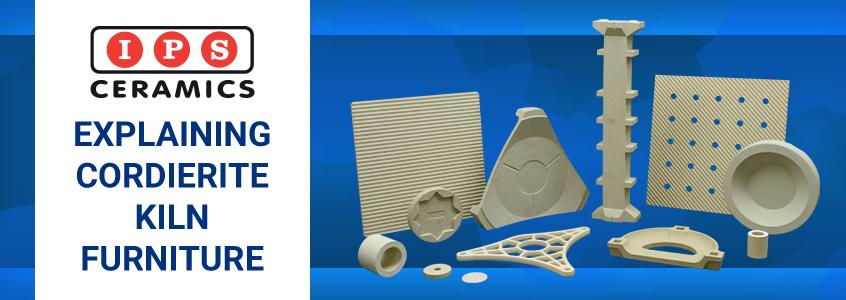

The term “kiln furniture” describes a range of products used by many industries to support items during heat treatment processes. If you have a ceramic item that needs firing in a kiln or furnace, you will probably need kiln furniture to ensure it keeps its shape, doesn’t break during firing, and don’t stick to/damage your kiln.

IPS offers an immensely popular range of kiln furniture products made from cordierite. What types of products are in the range, what do they do, who uses them, and why cordierite? Read on to find out…

What are the Most Common Kiln Products?

- Kiln shelves, batts, tiles and plates

- Tubes and beams

- Props and fittings

- Profile setters

- Rollers

- Saggars

- Stools

- T-cranks, Y-cranks and pin-crank systems

- Complete system builds

Why Cordierite?

Kiln Furniture is typically used to support heavy weights in high temperatures. Cordierite has a range of properties that make it perfect for these types of situations, including:

- Very low creep rates, ensuring a longer life for products being used in high temperatures.

- Extreme resistance to thermal shock cracking, allowing it to be used in applications involving rapid heating and cooling rates.

- Excellent stability at high temperatures, meaning that cordierite products can be thermally cycled hundreds (sometimes thousands) of times without degradation.

- Low density, enabling the production of more lightweight products which save energy with every firing.

What Industries Use Cordierite Kiln Furniture?

- Tableware – Tableware items such as plates and bowls have distinctive shapes which must remain consistent throughout production runs. Kiln furniture supports these products, helping them retain their shape and avoid breaking during firing.

- Sanitaryware – Sanitaryware products need support for the same reasons that tableware does. The sanitaryware industry usually uses furniture such as extruded batts which are capable of holding stronger loads, allowing them to support their much bigger and heavier products.

- Powder Metallurgy – Kiln furniture is used as a carrier during the sintering of powder metal parts to improve the dimensional accuracy achieved.

- Glass Manufacturing – Large extruded batts are used to support glass façade cladding panels during their firing processes. It is also useful for slumping, a process where glass sheets are placed over a mould and heated until they warp, falling into the mould and taking its shape. In this application, the kiln furniture would take the role of the mould.

A World-Renowned Supplier of Kiln Furniture

IPS Ceramics supplies one of the world’s broadest ranges of kiln furniture. Industries we serve include Sanitaryware, Tableware, Glass-Ceramics, Insulators, Heavy Clay, and more. Our speciality is complete system design. We also operate a design office and rapid prototyping facility to help clients with new and bespoke component designs.

If you have any questions about cordierite kiln furniture, please do not hesitate to contact us today.