Blog

Ozone Generators: Purifying the Air We Breathe by Using Ceramics

Posted by Tom Evans on September 14, 2020

With airborne viruses on everyone’s mind at the moment, it won’t come as a surprise that many people are looking into utilising air purifiers. One of the most efficient types of purifier is the ozone generator, a powerful type of machine used by industrial cleaning companies as well as laboratories and hospitals.

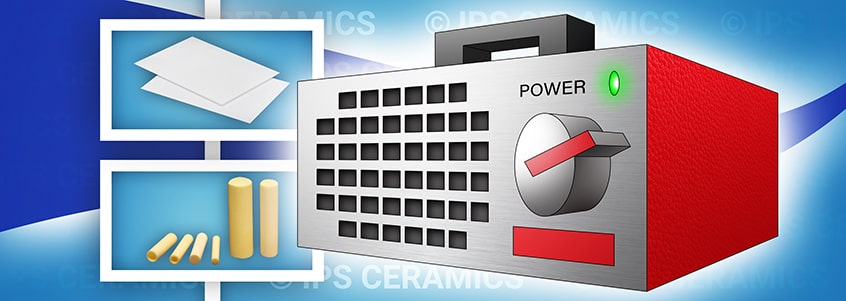

What many people don’t realise is just how important ceramics are to the functionality of the average ozone generator. This is understandable, given that the average ozone generator looks like a metal box – very few people think about what’s actually inside them – but if you were to dismantle the average generator, you would find several ceramic products which are fundamental to the way it works.

So how does the ozone generator work and why are ceramics so important to them? Let’s find out.

What is an Ozone Generator?

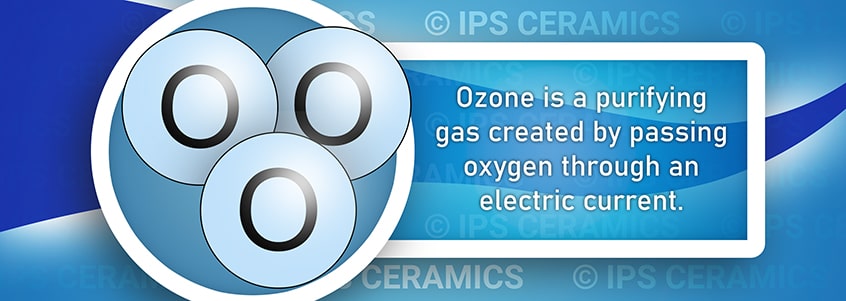

An ozone generator is a device which purifies the air around it, removing particulates, viruses and bad smells from the local atmosphere. As its name implies, it works by generating ozone and pumping it into contaminated areas. Ozone is a highly reactive gas which attaches itself to any pollutants in the air and destroys them, leaving only clean oxygen.

Ozone is created when oxygen gas is passed through a strong electric field. An oxygen molecule is made of two oxygen atoms. When it’s passed through high voltage electricity, the bond between the two atoms can be broken. Each ‘loose’ oxygen atom will then bond to an oxygen molecule nearby, creating a three-atom molecule which is called ozone.

The third atom is only loosely connected to the other two and easily reacts with other molecules in the air, at which point it breaks down those molecules and destroys them. If you produce enough ozone and pump it into an area with enough containment molecules, you can remove those molecules, purifying the air very quickly and effectively.

How are Ceramics Used?

There are two main types of ozone generator – ones which use ceramic or glass tubes and ones which use ceramic plates.

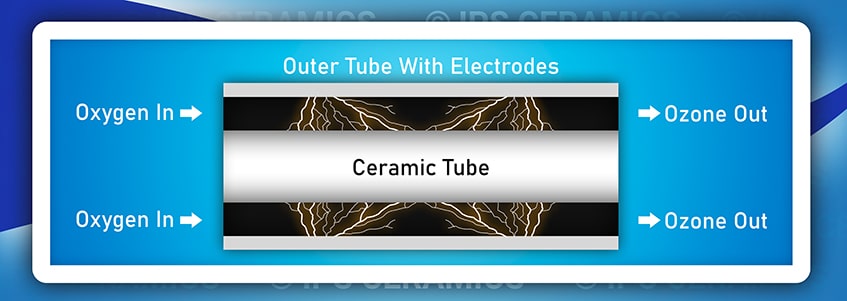

Tube Generator

In a simple tube generator, air is pushed down a small tube which has electrodes placed around its outer and inner sides. When electricity is passed from one electrode to the other, sparks are made, and when the air comes into contact with the sparks, this produces ozone. That said, this is a relatively inefficient process and it leaves a lot of oxygen unconverted.

Modern ozone generators typically use a ceramic tube placed inside the outer tube. The ceramic tube acts as a barrier, blocking a direct discharge between the electrodes. Instead, a much larger number of micro discharges occur which are spread over the surface of the ceramic tube, greatly increasing ozone conversion.

Alumina is often used to produce the ceramic tube. It is a strong, dense material, making the tube gas-tight. Alumina is also unreactive with oxygen and is very thermally stable

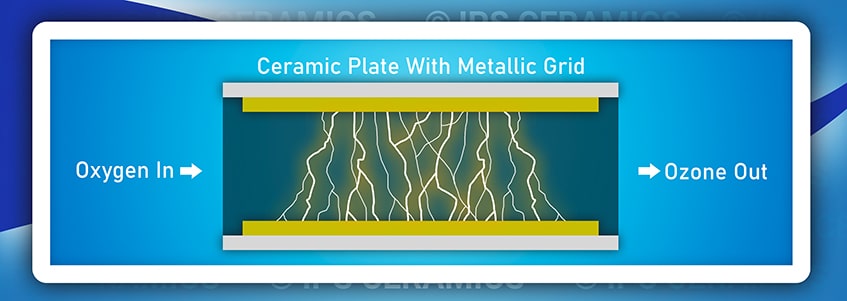

Plate Generator

Some generators use ceramic plates instead of ceramic tubes. For these machines, a metallic grid is adhered to a ceramic plate. Two of these plates are then placed in a generator with the metallic grids facing each other. An electric current is passed through the grid, resulting in a large number of electric sparks, and oxygen is then passed between the plates.

Once again, Technical Ceramics such as alumina are often used to form the plates in the generator. Alumina is an excellent insulator, allowing the metal grids to carry the high voltages needed to create the large amount of electric sparks. The alumina is also very thermally stable, giving a long life even when subjected to discharge sparks for extended periods. Finally, the fact that alumina can be formed into thin plates means that the generators end up being compact and light, making them easily stored and handled.

Conclusions

In the constant fight to ensure clean air and pleasant smells in even the most contaminated environments, technical ceramics are valued for their strong dielectric properties, their extreme toughness and their ability to be formed into a multitude of complex shapes.

For more on what technical ceramics we offer, how they can be used to improve your products, and what our company can do to help you and your ceramics requirements, please be sure to contact one of our experienced team members today. We have a vast range of services available for you, so whether you are looking for kiln furniture, silicon carbide or ceramics for EV batteries, do not hesitate to contact us.

IPS Ceramics is a renowned supplier of ceramic materials to laboratories, universities, and a wide range of manufacturers and industries. You can contact us here, bookmark our website, follow us on LinkedIn, Twitter or Facebook, or subscribe to our Mailing List.