Blog

IPS Cares #1: Painting Our Offices Green

Posted by Tom Evans on July 19, 2019

Between the Campaign Against Climate Change, documentaries such as Drowning in Plastic, and a range of recent news stories, environmentalism is once again a hot topic. IPS Ceramics believe that it is our collective duty to look after our planet and are dedicated to leading by example on this front.

We also believe in the economic and practical benefits of being environmental. We’ve found ecological practices to be cheaper and more effective than our previous ones, allowing us and our customers to benefit from a cleaner world, more cost-effective solutions and more efficient, better products.

These next three blog posts will show how we can work together to be greener and more sustainable. This post will show small changes which IPS have made to become greener in the office. Our next post will show how our solutions have helped customers to be greener while increasing their capacity, cost effectiveness and efficiency. And our third post will highlight other services we use to be green and can offer to you immediately to help you become greener too.

First up, the changes made to our office:

Example 1: Losing our Bottle[s]

When we started being greener, the first thing we looked at was how much bottled water we drank – about 50 bottles a month!

We made decisive action to cut them out entirely and have now replaced them with communal water dispensers. We went with a supplier who is as dedicated to being economical as us and who collects and reuses all their water dispenser bottles, minimising their carbon footprint as much as possible. We have also removed the plastic cups from our dispensers, replacing them with individual glasses that we intend to reuse for years to come (as the latest research suggests we should).

We’ve not just changed our water habits either: our coffee comes from Nespresso Coffee Pods which are similarly collected and recycled.

So schedule a meeting at our office and have a guilt-free drink on us.

Example 2: Bright Futures

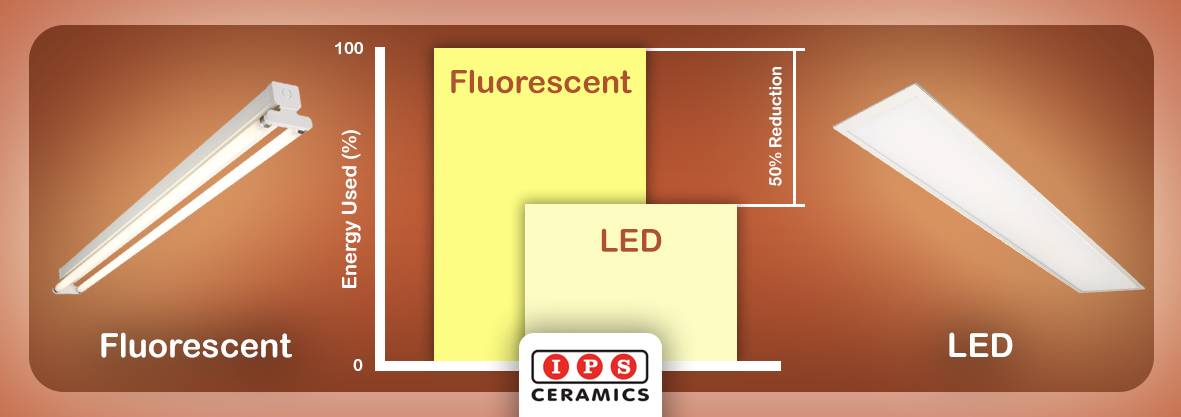

We are also in the process of replacing our office and warehouse lighting, transferring from outdated halogen lights to more efficient LED panels. These panels have reduced our energy usage by 50% so far, all while providing more light than the tubes they’re replacing.

This isn’t the only way we’ve improved our lighting: we’ve also taken the opportunity to replace opaque panels in our warehouse ceiling with transparent ones, increasing the amount of natural light and reducing our dependence on artificial lighting.

Through these methods, we’ve seen a direct example of how cost saving and environmental strategies can go hand in hand. Because environmentalism is about reducing our consumption of costly non-renewable energies, we find that implementing green techniques often goes hand in hand with a reduction in our running costs.

Given the successes detailed above, we’re now more dedicated than ever to constantly pushing and innovating in order to make our products more efficient than ever. In our next blog post, we’ll go over how we have worked with two of our customers in order to make their processes greener in ways which have been good to the environment, as well as their production and budgets.

Until then, if you’d like to find out ways in which we can work to make your ceramics firing processes better, please contact us and we’ll be happy to work with you.