Blog

How is Silicon Carbide Made?

Posted by Callum on August 19, 2021

Silicon carbide is one of the most common materials used to produce high-performance kiln furniture. It is often found in applications involving temperatures above 1300°C and its high resistance to creep (hot bending) ensures a long service life. How do you make such a strong, dependable material and who helped develop it? Let’s find out:

The Acheson Process

Most of the silicon carbide used in industry is manufactured through the Acheson Process. The process was invented by Edward Goodrich Acheson, by accident, whilst he was trying to find a way to make diamonds. The process involves mixing silica and coke together before heating them to a very high temperature, causing them to chemically react and form silicon carbide crystals, which are large enough to be seen by the human eye.

The Acheson Furnace

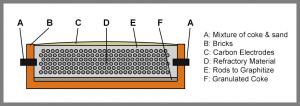

Acheson went on to develop a furnace design which is still the basis of most silicon carbide manufacturing today.

The furnace uses heating elements made from graphite rods which have an electric current passed through them, heating them to around 2500°C. As the surrounding mixture of sand and coke heats up, a layer of silicon carbide slowly forms around each graphite rod. The manufacturers remove this layer and, using various processes, turn it into a silicon carbide powder. One of the benefits of this material is that it doesn’t change (expand or retract) in lower temperatures.

That powder is then supplied to product manufacturers who use various shaping methods to produce their final items. These methods can include extrusion, pressing and casting. This material can be made to create burner nozzles, which are used to provide gas in a furnace.

The bulk manufacture of silicon carbide quickly took off and by the end of the 1890s, the Carborundum Company was producing 500 tonnes of silicon carbide per year. The silicon carbide production process is very energy-intensive and the first commercial plant to use the Acheson process was actually built close to Niagara Falls so that they could make use of the cheaper electricity available from the hydroelectric plant there.

IPS’ Ceramics Silicon Carbide

Silicon carbide is one of the hardest materials known to man and is excellent for use as an abrasive for cutting and grinding. It combines outstanding thermal shock resistance with a low density and high mechanical strength. Additionally, silicon carbide offers extreme hardness and abrasion resistance as well as outstanding chemical stability in aggressive environments.

IPS Ceramics offers all the principal types of silicon carbide and a wide range of kiln furniture products (including batts, beams, props, rollers, saggars and more).

If you would like more information on silicon carbide, the products that can be made from it, and how they’d help you, please contact us today.