Blog

Five Tips for Assembling Your Kiln Car Structure

Posted by Tom Evans on September 30, 2021

The centrepiece of any kiln firing setup is your kiln car – the strong combination of kiln furniture pieces which securely holds your ware as it gets fired. Depending on the complexity of your setup or the amount of ware you have to fire, assembling your kiln car can feel like a logic puzzle and maintaining it can be hard work. To help, we’ve collated our top five tips to ensure your kiln car gets assembled correctly and remains dependable for as long as possible.

1. Make sure the base is right

The kiln car base is the foundation upon which the rest of the structure relies, and failures of your firing system (such as batts with cracked corners) can often be attributed to the inadequate support of an uneven base. It is therefore important that the base is completely level, and that any parts of the base which will directly support the rest of the structure are constructed using appropriate materials.

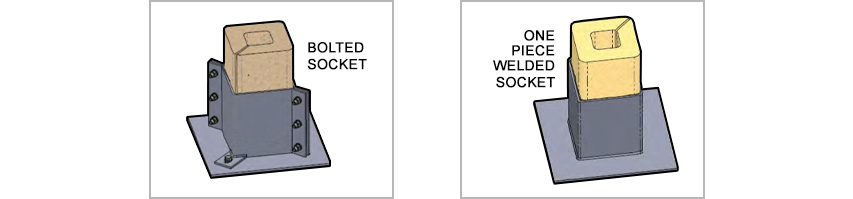

Where the kiln car base is mostly made of ceramic fibre or other lightweight insulating materials, it is normal for the design to include vertical posts or brick piers built up from the metalwork to support the weight of the kiln furniture structure. The posts are located in the car base using a metal socket. It is important that the posts can move slightly in the socket, as this helps the overall stability of the kiln car structure. Bolted sockets should be ‘finger-tight’ only.

2. Make sure everything is aligned

Where a solid kiln car base is used, the first layer of props should be positioned so that they are not directly above the overhanging area of the perimeter seal.

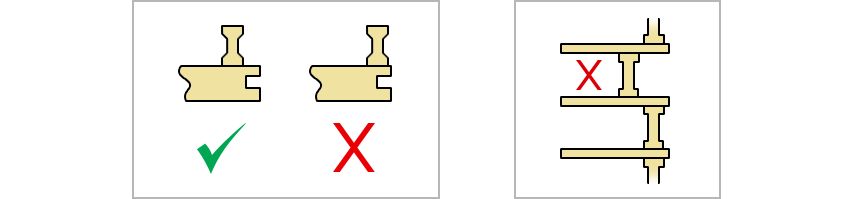

The same principle applies when building up the kiln car. It’s essential that the props used to support each deck are aligned directly above the supports below as this allows the weight of the ware to transfer down into the car base. Props that are out of alignment will apply bending stresses to the batts, leading to breakage, cracks or shortening their life.

3. Mark Your Dates

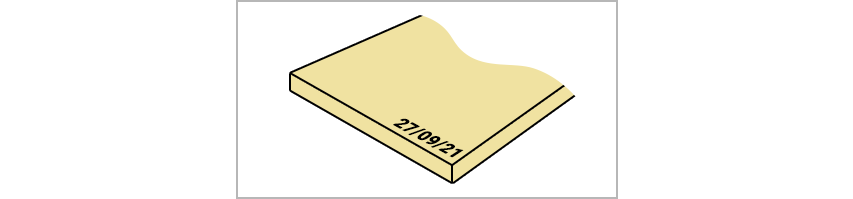

When components are first put into service, it is recommended that they should be marked with the date using a high-temperature pencil. This will allow you to monitor the performance and longevity of these products, helping you to get the most out of them.

4. Be Careful When Moving Them

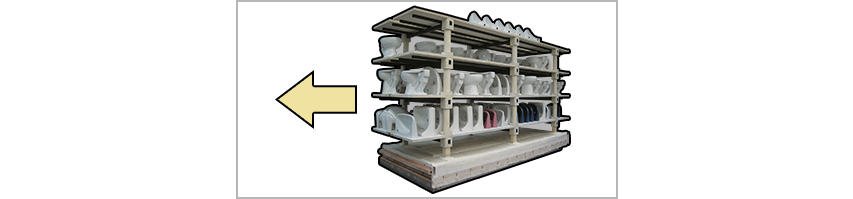

As the height of a kiln car structure increases, the stability inevitably decreases. Greater care must therefore be taken when moving taller cars outside of the kiln. Cars should only be moved at a slow walking pace, with the starting and stopping of the car done gradually. The tracks for cars must be kept clean; even a small piece of debris (such as a glazing pin) can cause a car to stop suddenly enough for the structure to tip over. If a car has several decks, it is dangerous to move the car with ware only placed on the top deck.

5. Use Batt Wash

Where products are placed directly onto batts, alumina wash can be used to help reduce sticking to surfaces. If this is applied too thickly, it can flake-off and cause contamination so batts should be coated as thinly as possible, using successive thin layers to maintain protection. You can read more about batt wash in our guide to cleaning cordierite batts.

For More Information

You can read more about our kiln car structures here. For a quick look at the pieces of kiln furniture which are usually used as kiln car components, check out our article here.

If you have any other questions or need any advice on how to best design, assemble and maintain your firing setup, whether in a kiln or a furnace, please feel free to contact us.

At IPS Ceramics, we supply many great services, including, but not limited to: technical ceramics, silicon carbide and EV batteries. If you require any of our industry leading services, please be sure to contact us today.