Blog

Cast Products

Posted by Liam Morgan on February 20, 2017

IPS Ceramics Develop a New Cast Product Range

IPS Ceramics has been manufacturing cordierite kiln furniture for more than 100 years as Acme, Diamond, Gimson, Hewitt and Dyson. We have a wealth of manufacturing experience and use various forming techniques (including dust pressing, extrusion and roller making) to produce a wide range of shapes for many industries.

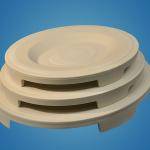

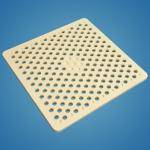

Recently, IPS have developed a new range of slip cast shapes that offer several advantages including greatly increased design flexibility and reduced set-up costs, but many users have reported that the major benefit is the smoother, more consolidated surface produced by casting.

IPS cast setters offer:

- A smooth contact surface that reduces sticking and plucking

- Dust-free setters that minimise kiln dirt and maximise yields

- Excellent stability at higher temperatures – can be used up to 1300ºC / 2350ºF

- High resistance to thermal shock during heating and cooling – reduced setter failure in fast firing cycles

IPS offer a wide range of cast shapes, including T-crank and Y-crank designs for glost firing, TFS or total-foot-support setters for once-fired ware. IPS Ceramics is also happy to work with individual dinnerware/tableware makers to produce bespoke profile-setter designs that are perfectly shaped to support your particular product lines during bone China and fine China biscuit firing.

Contact IPS Regarding The New Cast Range

If you would like more information regarding some of IPS Ceramic’s fantastic products, please contact us today. Whether you are looking at our brilliant new cast product range or some of our technical ceramics and silicon carbide, we can help you.