Cutting

Laser and Water Jet Cutting

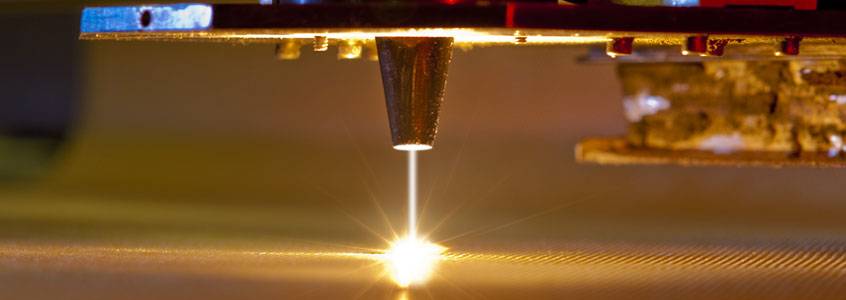

IPS Ceramics Laser Cutting Services

If we cannot supply a material in the exact size or shape you require, we may be able to cut an appropriately sized piece from a larger sized item.

Our cordierite kiln furniture batts and shapes can be easily cut using water-cooled diamond slitting blades. This can be a cost effective way of getting appropriately sized products when only smaller quantities are needed.

Laser & Water Jet Cutting for Technical Ceramics

Many of our technical ceramics (such as alumina, zirconia, etc.) are very difficult to machine due to their extreme hardness and abrasion resistance. Traditionally, expensive diamond grinding was the only option for machining these types of ceramics. IPS Ceramics have developed a more cost-effective cutting service for technical ceramic tiles and substrates which uses either water jet or laser cutting.

- Water jet cutting is an economical method of cutting technical ceramics which are up to 10mm thick. It can also be used to cut softer ceramics in sizes up to 25mm thick. The accuracy of cutting is generally +/- 1.0mm.

- For tiles and substrates below 1.5mm thick, we also offer a laser cutting service for machining flats, slots and complex shapes. The accuracy of cutting is generally +/- 0.05 mm.

Please note: we recommend that the internal corners of holes and slots have a radius that is at least equal to the tile thickness to reduce the risk of cracking.